Stretch Bending Solutions

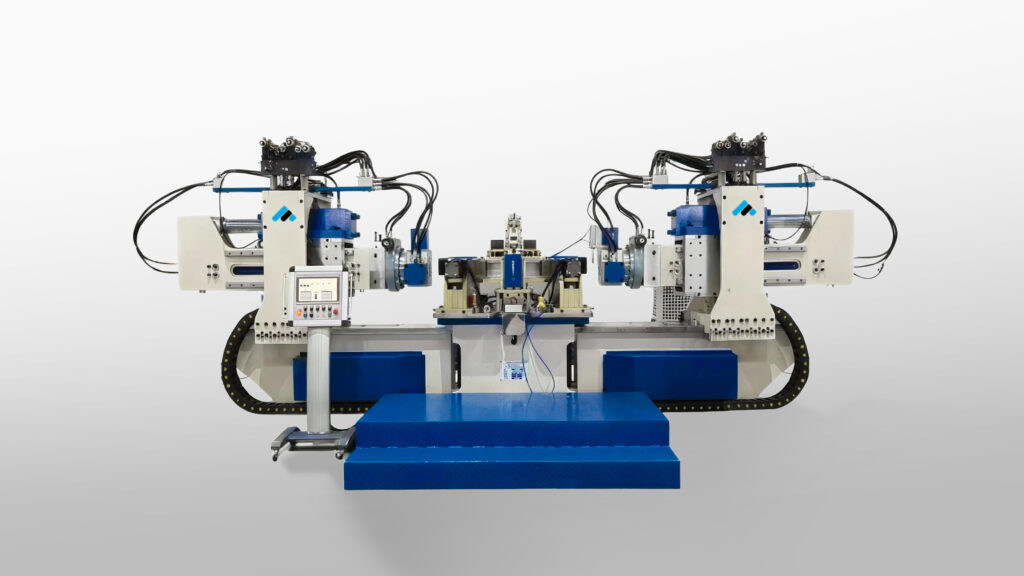

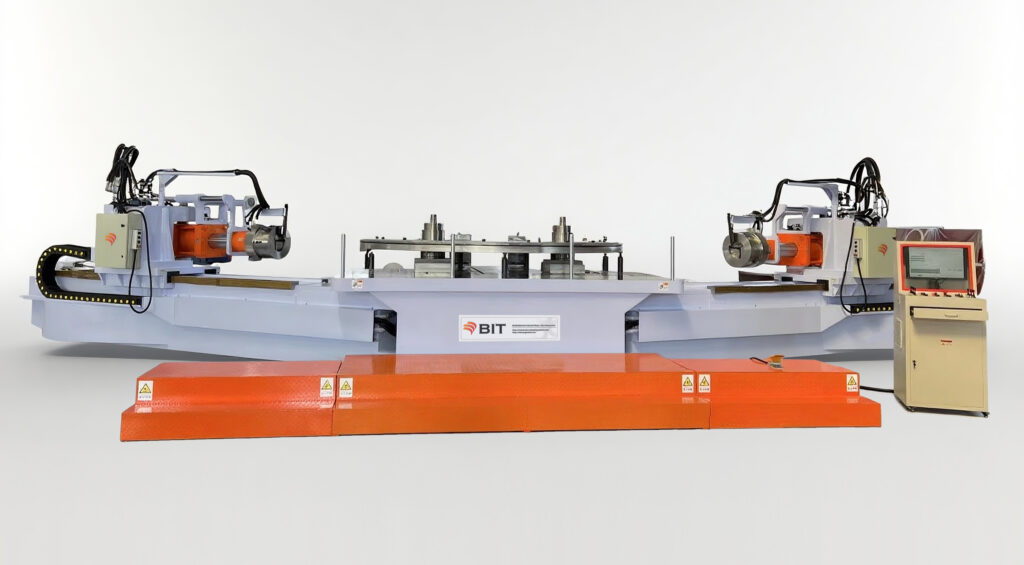

PBF CNC Stretch Forming Machine

Stretch Forming Equipment for Aluminum Extrusions and Sheets, as well as Steel Structures — Ensuring Dimensional Accuracy, Smooth Surface Quality, and Controlled Springback for Civil, Automotive, and Aerospace Applications.

WHAT IS

Stretch Forming Machine?

Stretch forming machines, also known as stretch bending machines, provide a precise and efficient solution for forming profiles and sheets from aluminum or steel materials.

Stretch forming equipment uses controlled tensile force and bending moments to shape metal profiles or sheets over precision dies. Designed for forming large curved components with high dimensional accuracy, they are widely used in the aerospace, automotive, and architectural industries for producing aluminum and steel parts with smooth, uniform curvature.

Stretch forming machines are widely used for shaping large aluminum alloy extrusions and sheets, especially in aerospace and automotive manufacturing. With precise control of tension and bending, stretch forming delivers high repeatability, smooth curvature, and excellent surface quality for complex structural parts.

Compared with conventional free bending, forming accuracy can be improved by 40%–60%, making it especially suitable for processing materials sensitive to springback, such as aluminum and titanium alloys.

Types of

Stretch Forming Machine

The Stretch Forming Equipment is available in various configurations such as Swing Arm Type, Dual-Column Type, Moving Table Type, and Lifting Die Type, designed to meet different forming requirements for aluminum alloy sheets, extruded profiles, aircraft skin panels, and steel structural components.

For aircraft skin panels, horizontal type (horizontal stretch forming machines) are generally used, due to their ability to handle large, thin panels with high precision and minimal deformation.

BIT‘s PBF Stretch Forming Equipment is offered in multiple control systems and forming capacities:

1. PBF-C Hydraulic Stretch Forming Machine – suitable for high-force forming of large aluminum or steel parts.

2. PBF-AS Servo-Controlled Stretch Forming Machine – ideal for precision forming with programmable control and minimal springback.

3. PBF-AU Hybrid Extrusion Stretch Forming Machine (Hydraulic + Servo) – combining power and accuracy for complex curvature components.

Available structure types: Swing Arm, Dual-Column, Moving Table, Lifting Die

Applicable materials: Aluminum Alloy Sheets, Aluminum Extrusions, Aircraft Skin Panels, Steel Structural Parts

Drive system: Hydraulic / Servo / Hybrid

Forming precision: ≤0.2 mm / 300 mm (typical flatness accuracy)

Applications: Aircraft skin panels, automotive bumper beams, roof rails, lighting housings, and architectural structures

Other Names: Stretch Bending Machine, Profile Stretch Forming Press, Stretch Forming Equipment, Extrusion Stretch Forming Machine

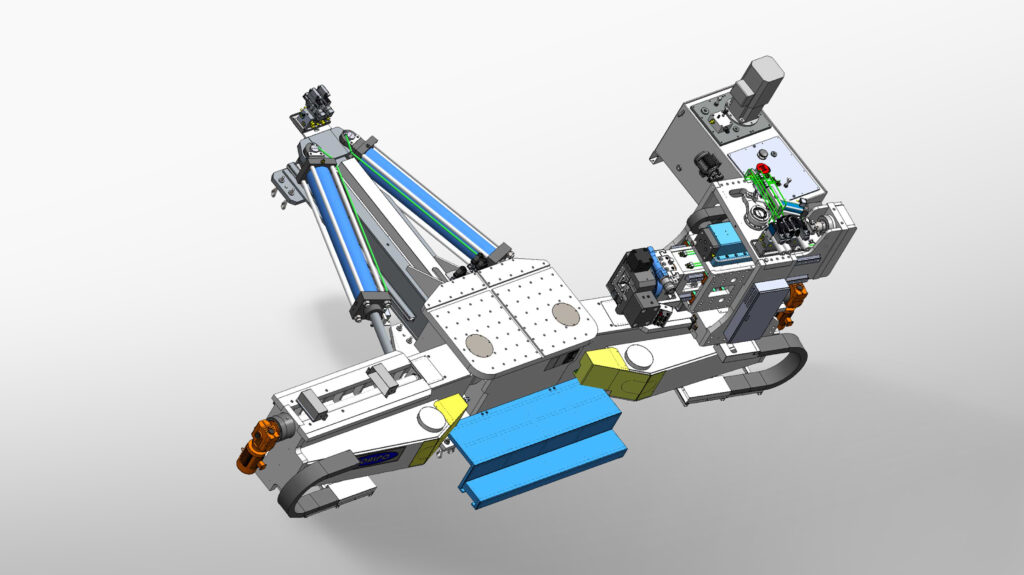

Structure, Performance & Accuracy

Stretch Forming Machines consist of a sturdy frame, adjustable swing or dual arms, forming tables, lifting dies, a movable control console, and a PLC or CNC hydraulic/servo drive system, specifically designed for processing aluminum sheets, extrusions, and steel structural components.

- Available Forming Force: 100 kN to 4000 kN

- Control System Options: PLC, CNC

- Drive System Options: Hydraulic / Servo / Hybrid

- Applicable Materials: Aluminum Sheets, Aluminum Extrusions, Steel Structural Components

- Forming Accuracy: ≤ 0.2 mm / 300 mm (typical flatness tolerance); for automotive parts, ±0.1 mm

Uses of

Stretch Forming Machine

Depending on customer requirements, BIT offer Stretch Forming Machines in various configurations, forming capacities, and control systems — suitable for different materials such as aluminum sheets, aluminum extrusions, and steel structural components, according to specific application needs.

Stretch Forming Machines are designed to shape metal sheets and extrusions into precise curved geometries under controlled tension and bending forces.

- Aerospace Industry:

Aircraft Skin Panels, Fuselage Frames, Wing Components, Structural Ribs, Seat Tracks - Automotive Industry:

Bumper Beams, Roof Rails, Door Frames, Window Trim Profiles, Lighting Frames - Architecture & Construction:

Curved Façade Panels, Decorative Aluminum Profiles, Steel Structural Arches, Roof Beams - Railway & Transportation:

Train Body Panels, Interior Frames, Structural Support Members - Energy & Industrial Equipment:

Solar Panel Frames, Lighting Enclosures, Machine Housings, Steel Support Profiles - Other Applications:

Precision Curved Components for Civil, Marine, and Defense Structures

Stretch Forming Process

Stretch Forming is a precision metal forming process in which profiles or sheet materials are stretched and bent simultaneously to conform to the inner or outer surface of a die. It combines bending moment and longitudinal tensile force to achieve accurate and repeatable shapes.

Aluminum extrusion stretch forming is an important industrial process used for manufacturing large-sized components that require high dimensional accuracy and large bending radii, such as aluminum extrusions and sheets.

During the stretch forming process, axial tensile force is applied while bending to modify the stress state of the material. The part is then stretched over the die to achieve the desired contour, minimize springback, and ensure high-precision forming.

The forming sequence consists of three main stages:

1. Pre-stretching — Material is stretched to its yield point.

2. Bending under tension — The part is pulled and bent to the die shape.

3. Compensation stretching — Additional stretching ensures precise geometry and dimensional accuracy.

FAQ

What causes profile contour deviation after stretch forming?

Cause: Contour deviation refers to the mismatch between the stretch-formed extrusion and the inspection template or forming die. The main causes include unstable springback behavior, variations in material properties and hardness between extrusion batches, large changes in bending radius, and inconsistent section dimensions of the extrusion. These factors result in unpredictable springback, causing the final profile to deviate from the intended curvature.

Solution: The die curvature should be compensated based on theoretical springback combined with correction values from stretching tests. When material inconsistency is expected, “over-pulling” with proper pre-compensation can help counteract springback. For cases with large radius transitions, a vertical hydraulic pusher can be added at the front of the forming die to keep the extrusion fully in contact with the die surface. During design, proper section dimensions and thickness must be ensured. For deviations caused by asymmetric cross-sections, pre-stretching force can be appropriately increased to maintain balance.

What are the causes of surface defects (wrinkles, cracks, dents, side scratches) during stretch forming of extrusions?

Cause: During stretch forming, the area below the neutral axis is subjected to longitudinal, radial, and width-direction compressive stresses. These stresses cause material contraction and radial thickening, and once they exceed the material’s stability limit, internal wrinkles appear. Extrusions with a low thickness-to-width ratio are more prone to instability. Asymmetric cross-sections, thin webs, or insufficient stretching force also increase the likelihood of wrinkling. Cracks are mainly caused by excessive tensile force combined with insufficient flange-release stress. Edge wrinkling (similar to “ear-like” deformation) results from inadequate edge control. Hollow extrusions are more likely to dent due to the lack of internal support, while side scratches typically originate from improper die clearance or unsuitable die materials.

Solution: Wrinkling resistance can be improved by increasing web thickness, optimizing the cross-section design, and adjusting stretching force. Hollow extrusions should be internally supported before bending with materials such as spring steel strips, PTFE inserts, or sand filling to prevent dents. Side scratches can be eliminated by improving die material and die clearance. Cracks and edge wrinkling can be resolved by optimizing the extrusion cross-section or adjusting the tensile and flange-release forces to achieve balance.

What causes twisting after stretch forming?

Cause: Twisting after stretch forming is primarily caused by asymmetric cross-sections. Uneven release and contraction of flange stresses lead to nonlinear torsional deformation after bending. Poor extrusion stability and local hardness variations also aggravate twisting.

Solution: Twisting can be reduced by increasing the stretching force or adding a vertical pusher at the die entrance to balance left-right stresses. Holding the stretch force for a short period after forming also helps stabilize the shape. Minor extrusion-related deformation can be corrected during the post-forming straightening process.

What causes perpendicularity (squareness) deviation after stretch forming?

Cause: Perpendicularity deviation also results from asymmetric sections, which create uneven flange stresses that shift the angle between the extrusion cross-section and the reference plane after bending. Small distortions caused by inconsistent extrusion quality also contribute to perpendicularity errors.

Solution: Die curvature compensation should be adjusted to better match the springback characteristics, and “over-pulling” can be used when necessary for pre-compensation. Any instability or deformation originating from extrusion can be corrected during the post-forming calibration process to ensure the final perpendicularity meets specifications.