PBF-AU CNC Stretch Forming Machine

Built for high‑performance forming of automotive bumper beams, sunroof guide rails, and roof racks & rails — delivering smooth multi‑speed operation, tight tolerances, and reliable production every time.

PBF-AU CNC Stretch Forming Machine

PBF-AU stretch forming machines are engineered for high-precision automotive manufacturing — purpose-built to meet the demanding requirements of bumper beams, sunroof guide rails, roof racks and rails profiles, and other complex vehicle structures.

Automotive structural components such as bumper beams, sunroof guide rails, and roof racks and rails profiles require stretch forming because of their demanding requirements for dimensional accuracy, surface quality, and structural integrity.

PBF-AU stretch forming machine provides the precise control needed to achieve smooth, accurate contours while fully preserving material strength and appearance. With its high-accuracy tensile control and multi-axis CNC motion, the PBF-AU is uniquely capable of forming these advanced shapes with minimal springback and exceptional consistency.

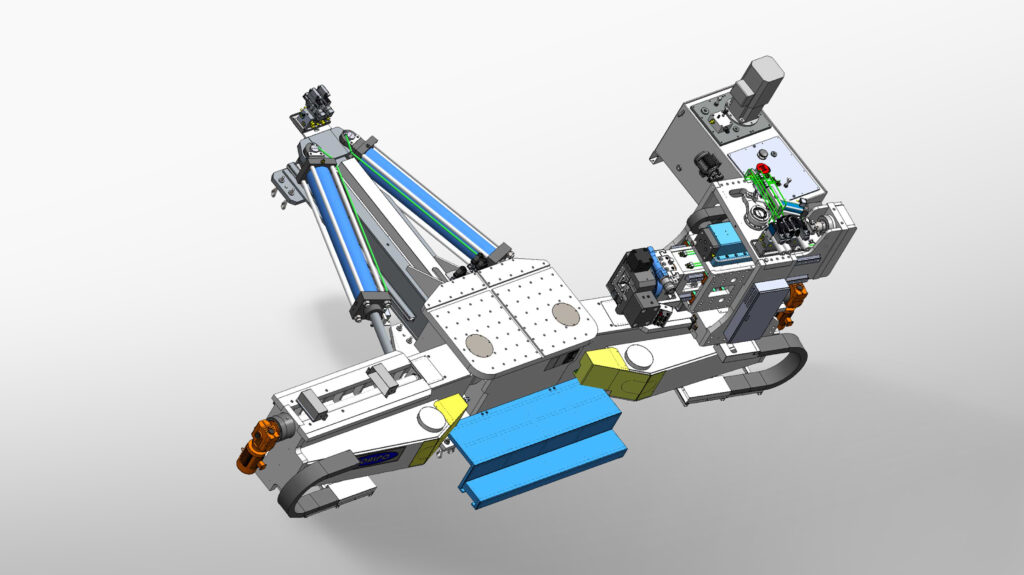

Flexible, Servo-Driven Dual-Arm Architecture

The PBF-AU series CNC Stretch Forming Machine adopts independently controlled servo motors for the left and right stretching axes, enabling precise analog control over each motion. The system is equipped with 12 dedicated hydraulic reserve ports, 3 four-core power connectors for sawing motors, and 4 independent pneumatic reserve interfaces. All auxiliary interfaces are fully integrated with the machine’s hydraulic and electrical systems, allowing rapid configuration based on different tooling requirements.

This advanced control platform of PBF-AU supports synchronous dual-arm bending for high-precision profile stretch forming, as well as independent single-arm operation, ensuring the two arms can function without interference during complex forming tasks.

The core structure utilizes a dual-arm bending mechanism, with an electronically controlled servo axis driving the primary bending arm. The stretching-arm elevation and extension axes are also servo-driven, providing smooth, coordinated motion throughout the forming cycle. The mandrel-insertion sub-axis is controlled by a bidirectional hydraulic valve, ensuring reliable core insertion and extraction during profile forming.

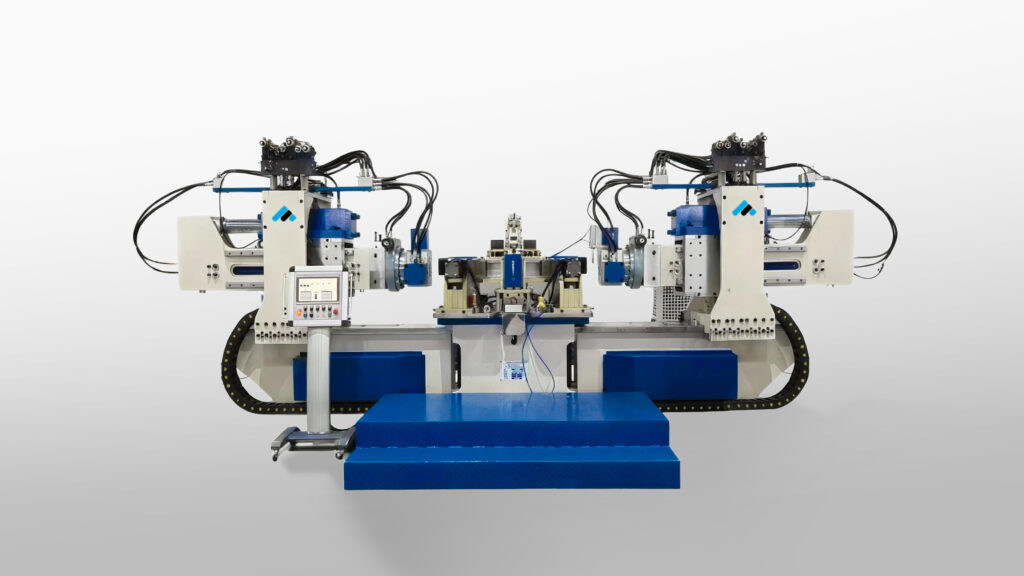

Electro-Hydraulic Servo System for Precision Stretch Forming

By employing an electro-hydraulic servo control strategy, the PBF-AU precisely regulates flow and pressure across all actuators.

Both stretch arms use independent servo motors and gear pumps to deliver precise torque control, synchronized motion, and accurate stretching force. A dedicated auxiliary servo-hydraulic group handles reserve circuits, column movement, and clamping.

Its fully integrated servo-hydraulic system, featuring military-grade Xingchen servo motors paired with German-made gear pumps, ensures high forming accuracy and rapid response. This advanced configuration also reduces energy consumption, delivering a highly efficient and reliable stretch-forming solution.

Precision Multi-Axis Motion Control

The PBF-AU features advanced motion control for precise and reliable stretch-forming, making it ideal for complex automotive profiles.

Bending motions are precisely controlled to achieve multi-speed operation and accurate arm positioning. The chuck rotation and Z-axis lifting mechanisms allow multi-position control and variable speed switching. Horizontal return of the stretching cylinder is guided by a cylinder locking mechanism, while column translation is powered through a T-slot ball screw system. Integrated encoder feedback simplifies mold changeovers and ensures consistent, precise positioning.

With high-quality servo motors, imported gear pumps, and Eaton proportional valves, the PBF-AU series CNC Stretch Forming Machine delivers superior forming accuracy, rapid response, and energy-efficient operation.