Fluid Cell Sheet Hydroforming Solutions

Fluid Cell Presses

Precision Metal Forming: Complex Geometries Or Free-Form Surface Components With Excellent Repeatability And Part Quality.

WHAT IS Fluid Cell Presses?

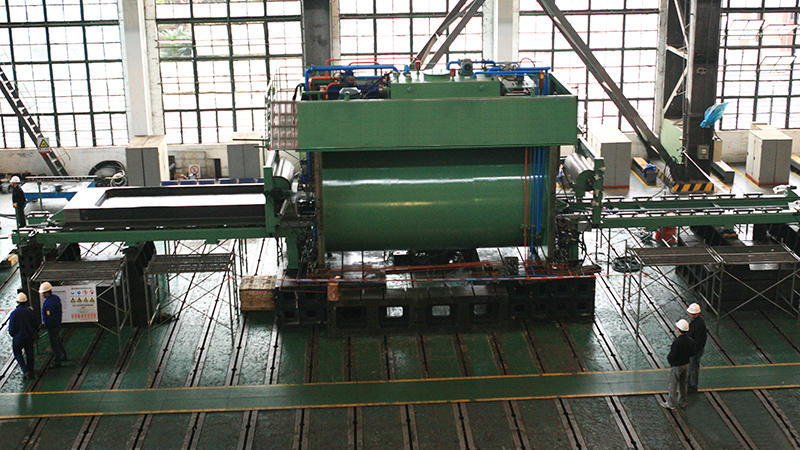

Fluid Cell Presses, also known as fluid cell forming, provide a low-cost solution for sheet metal forming.

Fluid Cell Sheet Hydroforming Presses uses high pressure, ranging from 800 bar (11,600 psi) to 1,200 bar (17,400 psi), applied to a flexible rubber diaphragm. Designed for prototyping and low-volume part production, they precisely shape metal sheets into complex forms.

Fluid Cell Presses is widely used in forming high-toughness alloys, especially for jet engine components. With cycle times ranging from 30 seconds to 2 minutes, depending on tool size and pressure, Fluid Cell Presses deliver efficient and reliable performance.

For small to medium-sized aerospace, commercial lighting, and medical equipment manufacturers, the Fluid Cell Sheet Hydroforming offers higher productivity, greater design flexibility, and faster prototyping speeds.

How Fluid Cell Presses Work

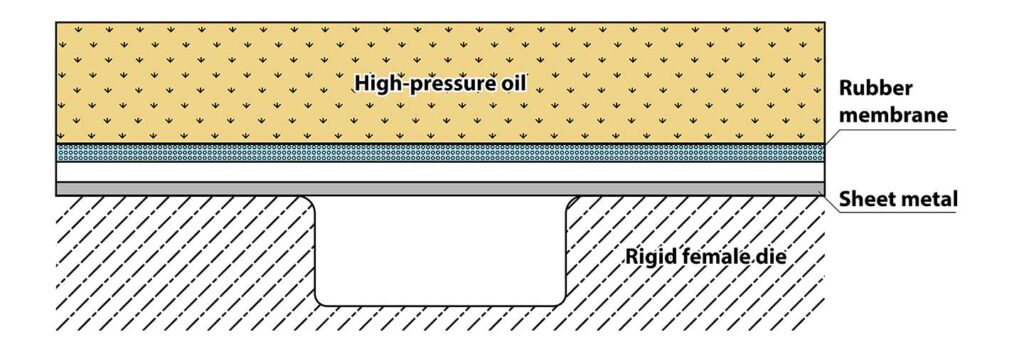

The Fluid Cell Sheet Hydroforming process combines a single rigid half-die with a flexible rubber diaphragm to form metal sheet components under uniform high static oil pressure.

This method requires only one rigid half of the die; the other half is a large soft rubber bladder filled with high-pressure fluid. It presses the flat metal blank around the tool, forming a new part under 800 bar of pressure in a short time. Fluid Cell Presses significantly reduces tooling costs and eliminates multiple forming operations, intermediate heat treatments, and operator dependency.

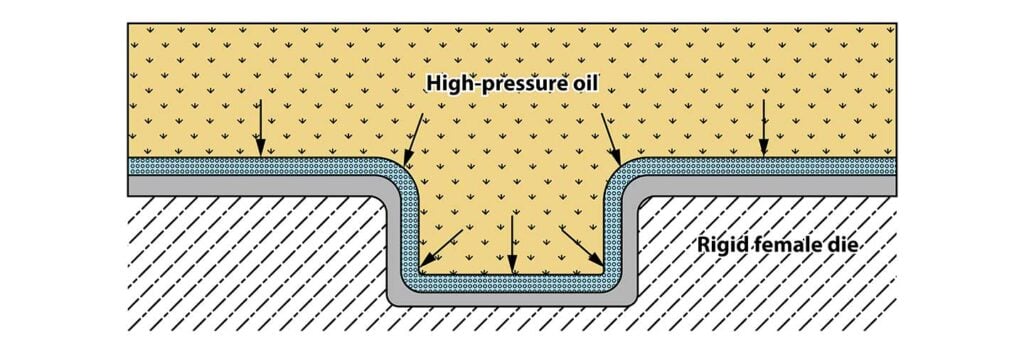

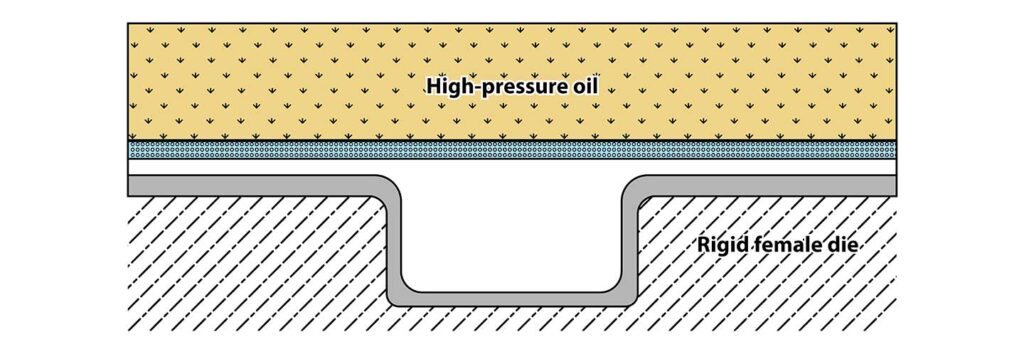

Fluid Cell Presses uses hydraulic oil to form parts under pressure: pressurized, the bladder descends, and the part is formed; depressurized, the soft rubber bladder retracts under vacuum, and the conveyor table moves the workpiece out, ready for the next forming cycle.

Cycle times within the press vary depending on the thickness of the part.

Advantages of Fluid Cell Sheet Hydroforming

Fluid Cell Sheet Hydroforming supports forming complex shapes with excellent repeatability and high part quality. In the aerospace industry, the need for manual adjustments and intermediate heat treatments is often reduced or eliminated.

Proven technology: Reliable, fast, and cost-effective.

Increased productivity: High pressure reduces process steps and minimizes the need for secondary operations, boosting efficiency.

Versatile tooling: Allows multiple forming tools in a single operation.

Reduced surface wear: Minimizes downstream finishing requirements.

Stronger, thinner parts: Achieves durability with reduced material thickness.

Flexible: Simple tooling enables rapid design-to-production transitions.

With a high forming pressure of 800 bar (11,600 psi), the Fluid Cell Presses produces precise parts with tight tolerances, minimizing or even eliminating the need for secondary manual operations.

USES OF Fluid Cell Presses

Whether it’s aerospace, power generation, medical devices, commercial lighting, or other products, BIT offers the latest industry equipment and technical expertise to help you solve engineering challenges.

Thanks to BIT’s Fluid Cell Sheet Hydroforming Press forming capabilities, even smaller manufacturers can now produce long, deep-drawn complex shapes without the need for expensive sheet metal bending and forming machines.

Typical Applications of Fluid-Formed Components:

Aerospace parts made from aluminum alloys, stainless steel, and titanium.

Trays and other surgical equipment for medical use.

Components for prototyping and low-volume production.

Fixture housings and reflectors for commercial lighting.

In China, BIT’s Fluid Cell Presses has built a solid reputation in the aerospace industry for manufacturing fuselage, engine, and aerospace sheet metal components. This sector requires a limited number of high-quality, diverse parts, which makes this technology particularly well-suited to meet those needs.

Fluid cell forming is perfect for prototyping and small-batch production while also serving industries like automotive, trucks, food processing, appliances, and building facades.

Frequently Asked Questions

What is Fluid Cell Sheet Hydroforming for Fluid Cell Presses?

Fluid Cell Sheet Hydroforming is a metal forming process used in fluid cell presses, where a flexible rubber diaphragm(fluid cell) and hydraulic pressure are employed to form sheet metal into precise shapes.

In this process, a single rigid tool (usually the punch or die) is used, while hydraulic pressure is evenly applied through the rubber diaphragm(fluid cell) and fluid medium, pressing the sheet metal against the tool surface.

This method eliminates the need for matching dies, reduces tooling cost, and ensures uniform pressure distribution, making it ideal for aerospace, automotive, and architectural applications that require high surface quality and dimensional accuracy.

How Does Fluid Cell Sheet Hydroforming Deliver Versatility and High Precision?

Versatility: Fluid Cell Sheet Hydroforming delivers versatility and high precision through the use of a flexible rubber diaphragm and uniform hydraulic pressure, which allows the process to form complex shapes with consistent thickness and smooth surfaces.

Because only a single rigid tool is needed, it enables fast changeovers, reduced tooling costs, and compatibility with various materials—from aluminum and stainless steel to titanium alloys.

High Precision: The uniform pressure also ensures tight dimensional tolerances and excellent repeatability, making it ideal for aerospace, automotive, and precision engineering applications.

Process of Fluid Cell Sheet Hydroforming

The Fluid Cell Sheet Hydroforming process is as follows:

- Place the die on the worktable, position the sheet metal on the rigid die, and use a flexible rubber diaphragm as the upper die.

- The worktable is loaded into the Fluid Cell Press, and air between the lower die, sheet metal, and rubber diaphragm is evacuated through vent holes to create a vacuum.

- High-pressure oil is pumped into the system, causing the rubber diaphragm to expand and press the sheet metal. This ensures uniform force distribution, forcing the sheet to closely conform to the die and achieve the desired shape.

- Once the pressure inside the diaphragm reaches the set value, it is maintained for a specified dwell time. Afterward, the pressure is released, and the rubber diaphragm returns to its original position.

Three Key Considerations for Fluid Cell Sheet Hydroforming of Aluminum Parts

The Fluid Cell Sheet Hydroforming of the parts is as follows: blanking – solution heat treatment – cold storage – leveling – Fluid Cell Sheet Hydroforming – manual trimming. The blank material is 0.4 mm thick 2024-O aluminum alloy sheet.

- Solution heat treatment is carried out in a nitrate salt bath at 494–496 °C. After holding the sheet in the furnace for 15 minutes, it is immediately quenched in cold water for 1 minute, then transferred to hot water to clean the surface of residual salts.

- Since a large number of parts are formed in a single batch, the quenched material is stored in a −10 °C freezer prior to forming to slow natural aging and ensure the material is in optimal condition before forming.

- Quenching introduces residual stress in the sheet, causing overall distortion and varying degrees of surface buckling. A leveling machine is used to flatten the sheets and reduce the impact of quench-induced deformation on subsequent forming.

What Types of Fluid Cell Presses Are Offered?

BIT offers a structured Fluid Cell Press lineup tailored to forming capacity and production goals:

Circular Tray Models: (Ø700–Ø1,000 mm, up to 800 bar) – compact units for small parts, prototypes, and high-speed forming.

Rectangular Tray Models: (1.2 m × 2.4 m to 1.8 m × 3.6 m, 800–1,400 bar) – mid to large presses for multiple or large blanks in aerospace and automotive applications.

Heavy-Duty Production Systems: custom-engineered presses with shuttle trays, servo control, and digital monitoring for full-scale production.

All systems use a single rigid die and flexible diaphragm, ensuring uniform pressure, high accuracy, and superior surface finish.

Which Industries Can Benefit from Fluid Cell Presses?

Fluid Cell Presses are widely used across industries requiring precise sheet metal forming and smooth surface finishes.

Aerospace: forming of airframe panels, brackets, and structural skins with tight tolerances.

Automotive: production of body panels, trim parts, and lightweight structural components.

Defense: fabrication of high-strength alloy parts and ballistic panels.

Energy & Power: forming of turbine covers, pressure housings, and thin-wall enclosures.

Architectural & Decorative Metalwork: shaping of stainless steel, aluminum, or titanium sheets for façade or interior components.

Their versatility, high repeatability, and low tooling cost make Fluid Cell Presses an efficient choice from prototype development to full-scale production.

What Are the Benefits of Fluid Cell Sheet Hydroforming?

BIT’s Fluid Cell Sheet Hydroforming technology provides multiple advantages:

- Uniform hydraulic pressure for consistent forming

- Smooth surface finish with no tool marks

- Single rigid die design for lower tooling cost

- High forming accuracy with minimal springback

- Applicable to aluminum, stainless steel, and titanium alloys

These features make BIT an industry-leading provider of precision Fluid Cell Press systems.