Full-Radius Forming Accuracy and Across Complex Curves and Profiles.

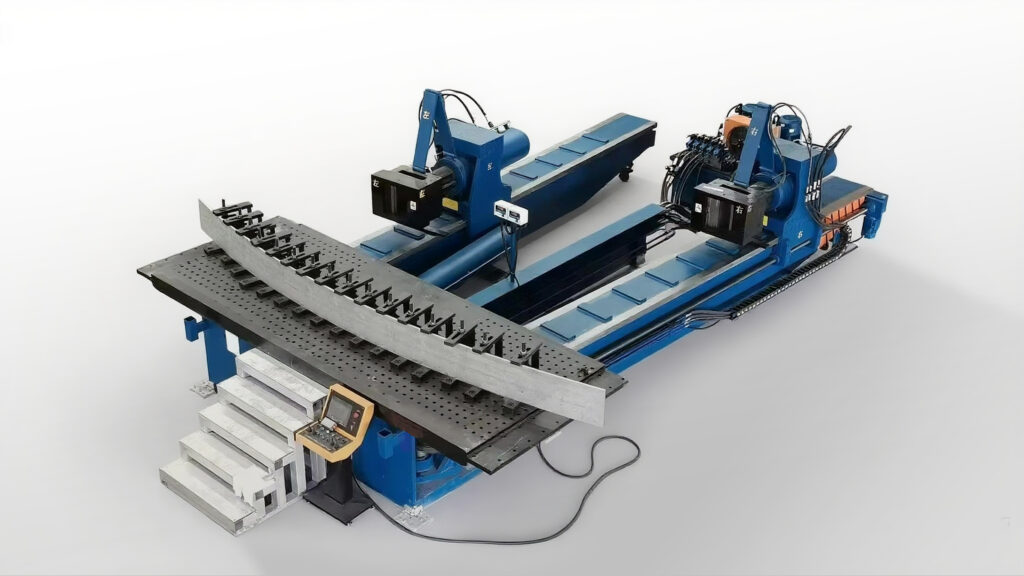

PBF-C Stretch Forming Machines

PBF-C Stretch Forming Machines

PBF-C stretch forming machines are designed for reliability and long service life — engineered to meet the demanding requirements of architectural and rail industries.

Each stretch forming machine is manufactured and tested in strict accordance with QB/8273-2009 – Technical Specification for Dual-Arm Hydraulic Stretch Forming Machines, and only fully qualified machines leave our factory.

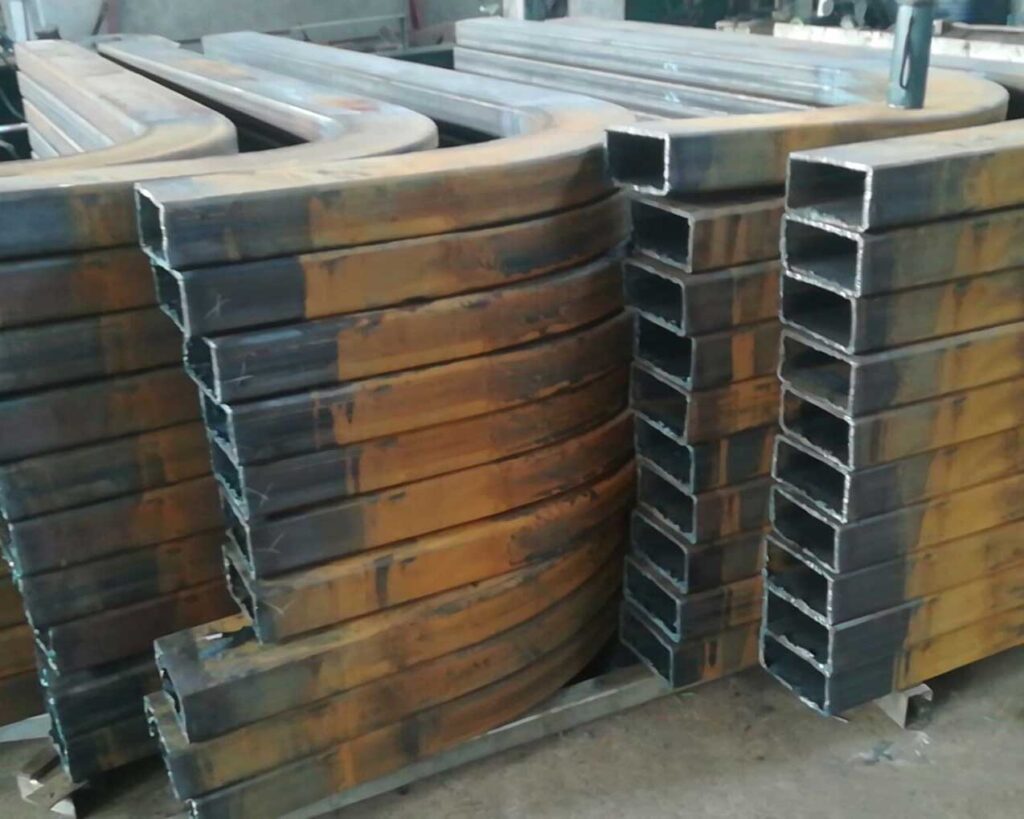

Our innovative “reverse stretch forming” mechanism delivers the necessary torque to achieve full-radius forming accuracy, ensuring superior product consistency across complex curves and profiles.

Modular, High-Performance Chucks

BIT insists on high-quality cylinders from professional manufacturers equipped with Japanese brand seals.. This ensures long-term stability, eliminating common oil leakage problems seen elsewhere.

The clamping chucks feature synchronized expansion and retraction, ensuring smooth operation, firm material holding, and effortless release. The modular design allows for quick assembly and disassembly, improving efficiency during production and maintenance.

Each chuck is designed with optimized clamping angles, customized for different machine models to prevent cracking and guarantee reliable performance under various forming conditions. This precision design ensures consistency, stability, and long service life.

Independent Dual Hydraulic Systems

PBF-C stretch forming machine adopts two completely independent hydraulic systems — one for clamping and bending, and the other for stretching. This separation eliminates interference between pressure zones, ensuring stable operation and precise forming control.

An integrated hydraulic valve block provides a compact, organized structure that simplifies inspection and maintenance while enhancing system reliability.

The pipeline layout combines flexible and rigid connections, achieving both functional efficiency and a clean, professional appearance that reflects advanced engineering design.

Maintenance-Free Bearing Design

The main arm’s rotary shaft adopts a self-lubricating composite sliding bearing, ensuring smooth and precise motion. This innovative bearing structure eliminates the need for manual lubrication, simplifying maintenance and operation.

An integrated hydraulic valve block provides a compact, organized structure that simplifies inspection and maintenance while enhancing system reliability.

While some manufacturers have attempted to imitate this structure, BIT mastered its core technology, guaranteeing long-term reliability, stability, and superior forming accuracy.

Top-Quality Hydraulic and Electrical Components

Each system is precisely calibrated to deliver smooth pressure response and accurate synchronization between the stretching and bending actions. The robust control architecture minimizes downtime and maintains high forming repeatability.

A precision stroke limit device is built into the PBF-C stretch forming machine, enabling accurate angle control during stretch forming, ensuring dimensional consistency and high-quality results for every production cycle.

To ensure long-term stability and consistent forming performance, BIT Stretch Forming Machines integrate hydraulic and electrical components from renowned global brands. Hydraulic valves are supplied by Taiwan Yuken, pumps by Jiangsu Hongda, motors by Shanghai Libo, and all electrical components by Chint — guaranteeing reliability and global service support.

Parameters of

PBF-C Stretch Forming Machines

| Item | PBF-C15 | PBF-C25 | PBF-C35 | PBF-C50 | PBF-C80 | PBF-C100 | PBF-C120 | PBF-C160 |

|---|---|---|---|---|---|---|---|---|

| Max. Stretch Force / Single Cylinder/KN | 150 | 250 | 350 | 500 | 800 | 1000 | 1200 | 1600 |

| Max. Bending Force / Single Cylinder/KN | 150 | 250 | 350 | 500 | 800 | 1000 | 1200 | 1600 |

| Max. Swing Arm Rotation Angle | 95° | 95° | 95° | 95° | 95° | 95° | 95° | 95° |

| Stretch Length/mm | 1800~6000 | 1800~6000 | 1800~6000 | 1800~6000 | 1800~6000 | 1800~6000 | 1800~6000 | 1800~6000 |

| Max. Forming Section/mm | 150*150 | 200*200 | 200*200 | 300*300 | 300*300 | 300*300 | 300*300 | 400*400 |

| Min. Bending Radius/mm | 300 | 400 | 400 | 800 | 900 | 1000 | 1000 | 1200 |

| Max. Bending Radius Angle | 180° | 180° | 180° | 180° | 180° | 180° | 180° | 180° |

| Min. Bending Radius Angle | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° |

| Number Of Cylinders | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Horizontal Rotation Angle Of Stretch Cylinder | ≥35° | ≥35° | ≥35° | ≥35° | ≥35° | ≥35° | ≥35° | ≥35° |

| Stretch Displacement Accuracy/mm | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.3 | ±0.3 |

| Stretch Cylinder Stroke/mm | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 |

| Stretch Cylinder Diameter | D120/d80 | D140/d80 | D180/d120 | D200/d120 | D260/d140 | D280/d160 | D320/d200 | D360/d8200 |

| Stretch-Bending Cylinder Diameter | D120/d60 | D140/d70 | D160/d90 | D180/d80 | D250/d120 | D260/d120 | D280/d110 | D320/d140 |

| Repositioning Accuracy | ±0.5° | ±0.5° | ±0.5° | ±0.5° | ±0.5° | ±0.5° | ±0.5° | ±0.5° |

| Plunger Pump | 25YCY+16YCY | 25YCY+32YCY | 25YCY+40YCY | 40YCY+63YCY | 40YCY+63YCY | 63YCY+80YCY | 63YCY+80YCY | 80YCY+108YCY |

| Power Supply / Power | 13kw | 13kw | 18.5kw | 26kw | 26kw | 40.5kw | 40.5kw | 52kw |

| Table Dimensions/mm | 2000×1500 1200×1200 800×800 | 2000×1500 1200×1200 800×800 | 2000×1500 1200×1200 800×800 | 2000×1900 1200×1200 800×800 | 2000×1900 1200×1200 800×800 | 2000×1900 1200×1200 800×800 | 2000×1900 1200×1200 800×800 | 2000×1900 1200×1200 800×800 |

| Hydraulic Tank Capacity/L | 500L | 600L | 600L | 1000L | 1000L | 1400L | 1400L | 1800L |

| Max. Hydraulic System Pressure | 25Mpa | 25Mpa | 25Mpa | 25Mpa | 25Mpa | 25Mpa | 25Mpa | 25Mpa |