Ever wondered what secret math powers allow flat metal sheets to magically transform into sleek curved surfaces — without wrinkles, cracks or drama? 🚀 Dive into our quick-and-dirty guide to stretch forming: we break down the core formulas (stretch ratio, strain rate, forming force, and length calculations) so you don’t need a PhD in metal-bending to understand. Whether you’re bending aluminum vents or crafting sleek architectural trim, this article gives you the tools (and laughs) to master the curve 👍.

Curious how far you can bend before things start to look like origami gone wrong? Grab a calculator and let’s stretch some limits — literally.

Stretch Forming Calculation Formulas

The success of stretch forming largely depends on precise calculations. Here are some key formulas and techniques utilized in the process:

Formulas for Stretch Forming

1. Stretch Ratio Formula:

- Stretch Ratio (SR) = (L2 – L1) / L1

- Where L1 is the initial length of the material and L2 is the final length after stretching.

2. Strain Rate Formula:

- Strain Rate = (Final Length – Initial Length) / Initial Length × 100%

Key Techniques in Stretch Forming:

1. Understanding Material Properties:

- Before performing stretch forming, comprehending the material’s properties is crucial. Factors like elasticity, ductility, and yield strength impact the forming process.

2. Forming Force Calculation:

- The force required for stretch forming can be calculated using:

- Force (F) = Cross-sectional Area × Yield Strength

3. Determining Stretching Length:

- The required stretching length can be calculated using:

- Stretching Length = (Final Length – Initial Length) + Necessary Overstretch

Stretch Forming Calculator Overview

If all those stretch-forming formulas made your head spin a little 🤯— don’t worry, you’re definitely not alone. That’s exactly why we created the calculator below. Just enter a few basic numbers (initial length, final length, cross-sectional area, yield strength… all that fun stuff ✨), click the button, and boom — instant results, zero stress.

To make things even smoother, we’ve already loaded a sample dataset for you 🎉. Think of it as the calculator gently patting your shoulder and saying, “Relax, I’ve got this.” You can compare your own inputs with the example results and quickly get a feel for how stretch ratio, strain rate, and forming force behave when things start stretching out — literally.

So go ahead — type, click, calculate. Easy math, happy forming 😄.

Stretch Forming Formula Verification Calculator

Enter the required values below to calculate stretch ratio, strain rate, forming force, and stretching length.

Key Parameters for Stretch Forming

| Material Type | Elasticity (E) | Yield Strength (YS) | Ductility |

|---|---|---|---|

| Aluminum | 68 GPa | 110 MPa | High |

| Steel | 210 GPa | 250 MPa | Moderate |

| Copper | 117 GPa | 220 MPa | High |

Understanding the material type, elasticity, yield strength, and ductility is critical for successful stretch forming. Different materials behave differently during the stretching process, as shown in the table above.

Elongation Requirements in Stretch Forming Aluminum Extrusions

In stretch forming aluminum extrusions, elongation is one of the most important criteria for determining whether a profile can be successfully formed without section collapse or cracking. A commonly used engineering approach estimates the deformation by calculating the difference between the outer and inner bending radii. This value, known as the deformation width, is expressed as t = Router – Rinner. The required elongation is then approximated using the simplified expression Elongation = (t / Rinne) * 100%. Although this is not a rigorous plastic-mechanics equation, it is widely accepted in industry because it provides a fast and reasonably reliable assessment of whether a given profile and temper can be stretch formed.

For 6063-T5 aluminum extrusions—one of the most commonly used alloys—the national standard typically specifies a minimum elongation of 8%. In practice, when the required elongation is 10% or less, most 6063-T5 profiles can be stretch formed without difficulty. When elongation requirements exceed 10%, successful forming depends strongly on the profile design. Profiles with thicker walls, closed cavities, symmetric force paths, simple cross-sections, and width-to-height ratios below one often tolerate elongation in the range of 10–16% during stretch forming. Conversely, when a profile does not meet these geometric and structural conditions, it is generally necessary to switch to softer tempers such as T0–T4. In the fully annealed T0 condition, 6063 aluminum extrusions may achieve elongation levels as high as 20–28%, making them suitable for demanding stretch forming applications.

Understanding the required elongation is essential for predicting whether an aluminum extrusion can be successfully stretch formed without cracking, excessive thinning, or profile distortion. The calculator below allows you to quickly estimate elongation based on inner and outer bend radii using the standard industry formula. By comparing the result with the typical formability ranges of common tempers such as 6063-T5 or softer tempers like T0–T4, engineers can better evaluate material selection, tooling requirements, and achievable bend radii before production.

Stretch Forming Elongation Calculator

Enter radii in the same units (mm or inch). Outer radius must be larger than inner radius.

Ultimately, determining whether an aluminum extrusion can be stretch formed requires a combination of material properties, cross-section design, wall thickness, cavity configuration, symmetry, and the required bending radius. The simplified elongation formula remains effective as a preliminary engineering tool, helping engineers quickly identify forming feasibility and select the appropriate material temper before conducting detailed simulations or tooling trials.

Conclusion

In conclusion, precise calculations and understanding material properties are essential for effective stretch forming. Using the formulas mentioned and considering material-specific parameters can significantly impact the success of the process. Mastering these calculations empowers metalworkers to create accurately formed products meeting stringent dimensional requirements.

Stretch forming, with its blend of science and technique, remains a cornerstone of modern metalworking, providing endless possibilities in shaping various materials for diverse industrial applications.

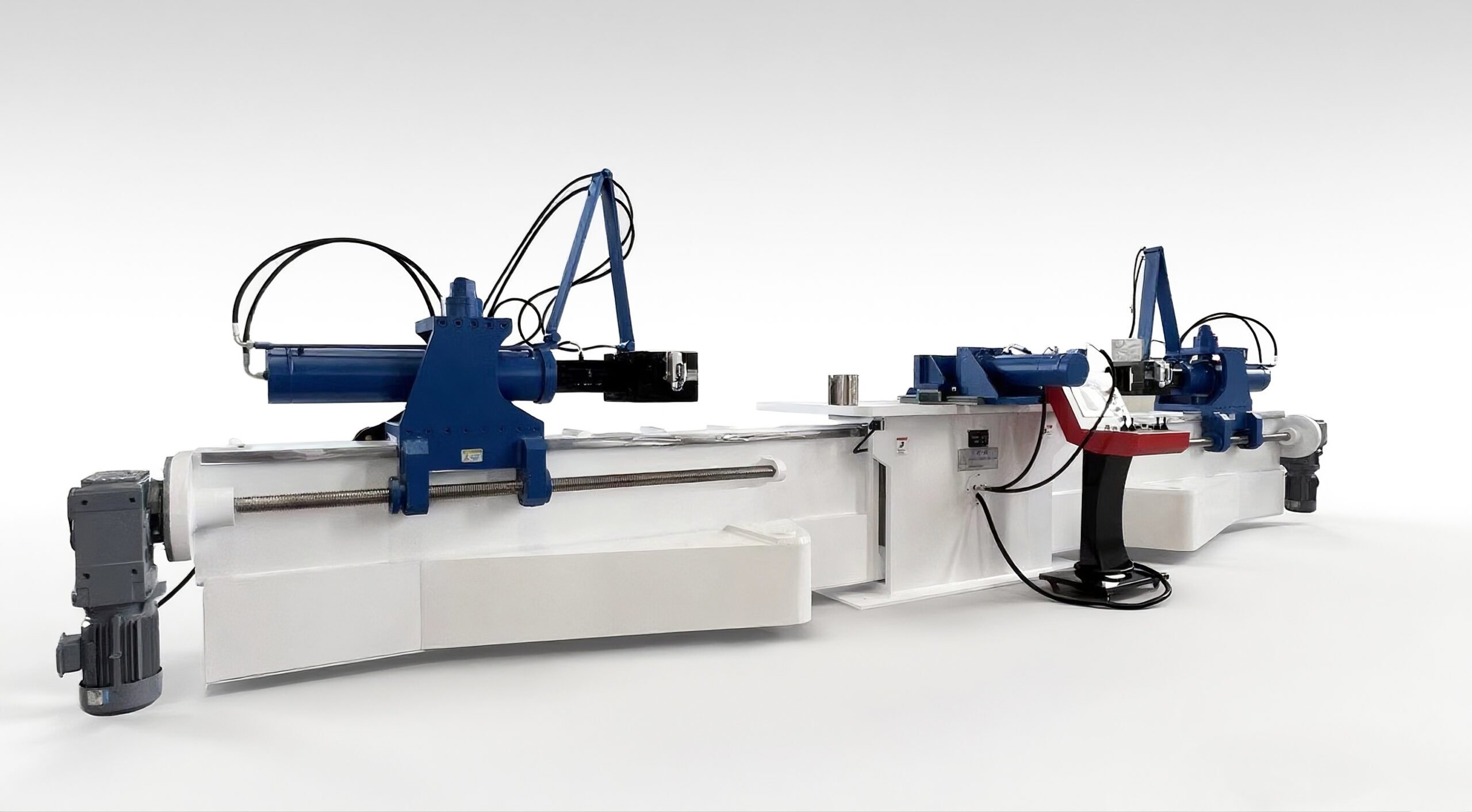

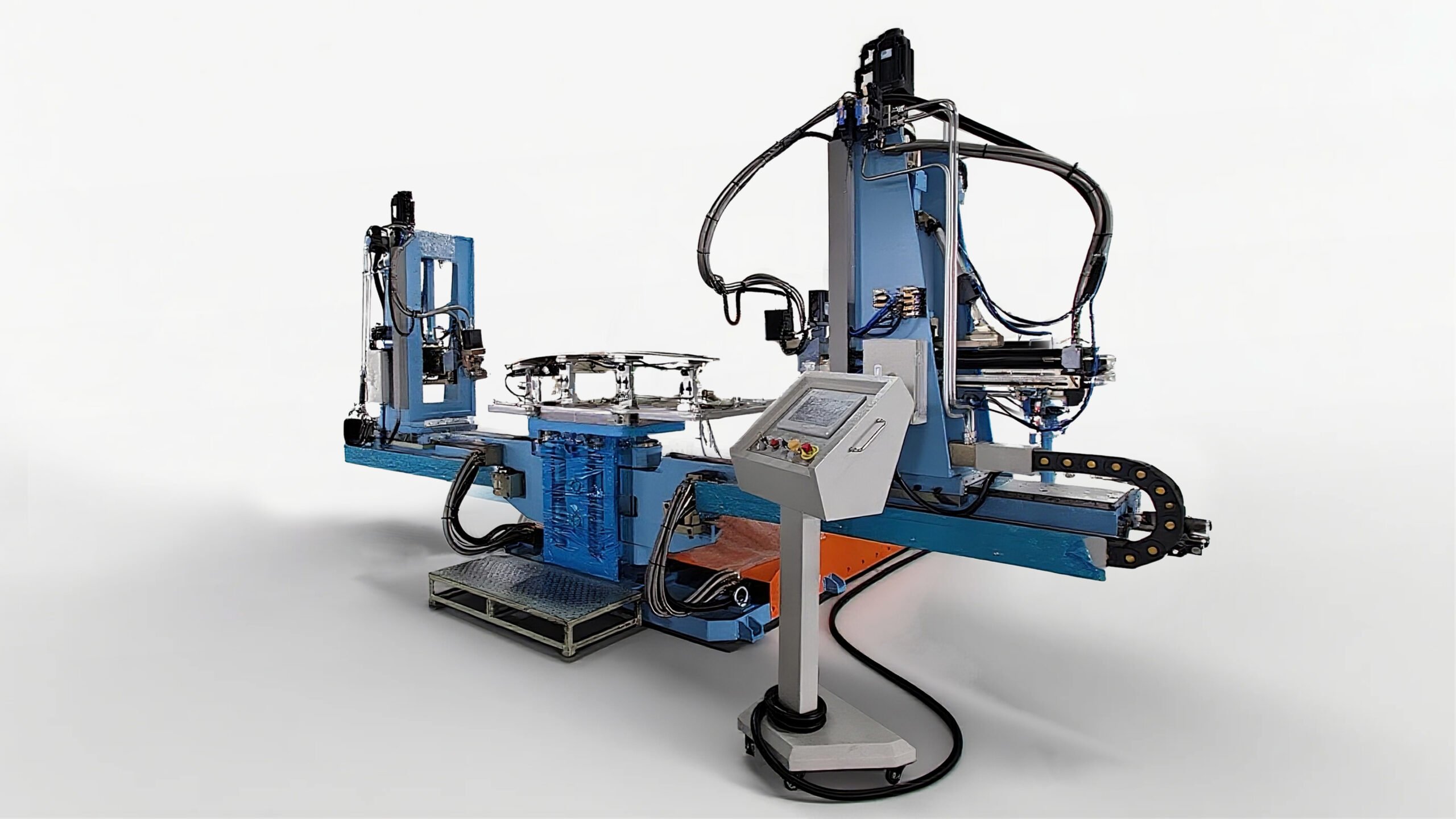

Curious to see the stretch forming magic in action? Check out our PBF stretch forming machines for precise, high-quality aluminum forming!