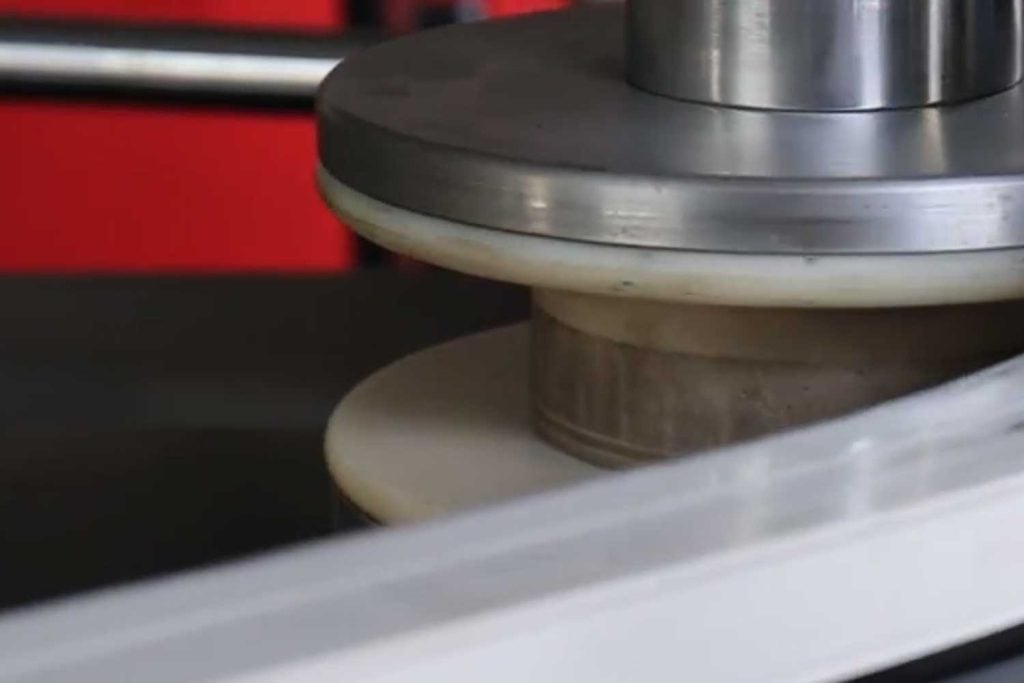

Roll bending process

Three-roll bending pushes an extrusion around three different rolls placed in a triangular shape. The rolls are adjusted to form a precise angle, up to a 360-degree rotation, that can roll horizontally or vertically. As the extrusion is slowly moved across the power-driven rollers, it begins to curve and bend.

Extrusions are limited to a single bend per cycle, meaning a higher angle of the bend would take longer to reach the desired angle. Though it may take longer, the maximum bend radius is unlimited. Symmetrical profiles are preferable for roll bending.

Bending process of three-roll section bender

Three different types of machines

Pyramidal angle roll

Pyramidal angle roll’s upper roller can move vertically up and down to pressurize the lower roller, so it cannot be pre-bent.

Single pinch angle roller

A single pinch profile bending machine (angle roller) requires inserting the profile metal twice to pre-bending both ends.

single pinch profile bending machines are generally only suitable for light-capacity applications. They work by pinching the profile between two vertically opposed rolls while the third bending roll moves upward to contact and then bends the profile.

These tend to be older machines that in most applications require removal and reinsertion of the profile to prebend both ends so although cost-effective they are more labor-intensive in a production setting than their modern counterparts.

Double-pinch profile bending machines

When 3-roll profile bending machines are double-pinch machines, their three rollers are all drive rollers, available in light to very heavy capacities, and do not require the operator to remove, flip, and then try to square the profile a second time after pre-bending. Profiles can be bent to the required diameter immediately following pre-bending because the material can be kept in the machine.

Side rolls are positioned to the right and the left of the top roll is on the same axis. The axis of each roll helps make the bend. The back-side roll also functions as a back-gauge to square the profile for proper alignment which eliminates the need for someone to assist the operator.

All BIT series profile bending machines adopt double-pinch bending

Bending process of four-roll section bender

Four-roller profile bending machines have a top roll, a pinching roll, and two side rolls. These steel plate rolling machines produce the fastest and most accurate bends.

The flat metal profile is placed in the machine on either side and “pre-bent” on the same side. The side rolls do the work of bending. The pinching roll holds the profile.

Profile held securely in place between the top and bottom rolls, while the side rolls move vertically to create the bend. The bottom roll moves up to hold the profile surface securely against the top roll while the side roll is raised to form an accurate pre-bend, minimizing the flat zone on the profile edge.

Plate feeding can take place on either side of a four-roll profile bending machine.

Side rolls are positioned to the right and left of the bottom roll and on their own axes. The independent axis of each roll helps make a perfect bend. The back-side roll (at the far side of the feeding point) also functions as a back-gauge to square the profile for proper alignment which eliminates the need for someone to assist the operator.

The profile is kept square without slipping during both pre-bending and rolling because of the constant secure clamping of the top and bottom rolls.

Four-roll machines do not require the operator to remove, flip, and then try to square the plate a second time after pre-bending. Profiles can be rolled to the required diameter immediately following pre-bending because the material can be kept in the machine.

Bending the back edge takes place after the cylinder is rolled allowing for a one-direction, single-pass operation.

Note: BIT series profile bending machine can work horizontally or vertically.

Pre-bending and bending process of BIT series profile bending machine

Rolling process

Pre-bending and bending process in 4 steps

Step 1

As shown in Fig.1, the right roller is in the lower limit position. The left roller is lifted and the main roller will be clamped to each other.

Step 2

As shown in Fig. 2, the right roller slowly rises, starts rolling, and performs pre-bending between the main roller and the left roller.

Step 3

The left roller is down and the right roller is raised. The material is sent to the left and the three rolls begin rolling, pre-bending between the main roll and the right roll.

Step 4

As shown in Figure 4, pre-bending and rolling end.

Why need pre-bending?

Pre-bending is to reduce the flat part in the bending process.

WHAT IS THE FLAT PART OF A COLD ROLLING BENDING?

After bending due to the position of the rollers the workpiece inevitably remains a flat part at the ends of the metal profile. This flat part is approximately half the length of the gap between the centers of the lower rollers.

HOW TO REDUCE IT?

Although the appearance of a straight part is considered to be a flaw of a symmetrical roller with 3 rollers, their simple structure, comfortable use, and low price still make them the most wanted model of roll metal section bending machines.

In addition, there are methods which we can use in order to easily eliminate this problem. You can find some of them below:

PRE-BENDING

Die bending method: First, the straight parts at both ends of the sheet are bent on a press according to the required bending radius. This solution involves bending the edges of the workpiece on a press brake before the roll bending process.

ADDING A “BASE” FOR THE WORKPIECE DURING THE PRE-BENDING

This method involves the installation of a “base” together with a workpiece designed for bending and performing the edge pre-bending process on the circular bending machine itself. The application of this method should take into account the possibilities of the circular bending machine and calculate the strength of the applied force on the “base” and the workpiece.

Leaving allowance at the ends – if you add an appropriate allowance at plate ends before the bending, you can, after the bending, cut off those parts into a desired bending shape.

ASYMMETRICAL MODEL

Regarding the asymmetrical models of roll bending machines with 3 rollers, the position of the rollers is better adapted to eliminate the flat edges of the sheet, in which case the lower rollers can also be mounted vertically.

Thus, in a model with an asymmetric position of the rollers, the lower rotating roller can be lifted up to the middle of the gap between the two rollers, while the other can be positioned in the appropriate position so that the starting part of the metal profile can be folded to form a circle. The flat edge can be eliminated on both sides by turning the rollers in half of the bending process by folding the back of the profile. Additionally, the workpiece can also be turned around after completion of one bending cycle and then the back part will become the front and both flat edges will be eliminated.