Steel is the most adaptable, regularly used structural steel.

Both H-beam and I-beams are structural steel beams used widely in the construction industry by civil engineering professionals.

To a novice, both are similar in shape to regular people, but there are significant differences between these two, which are essential to know, and people often ask that I-beam and H-beam are similar in shape, how do choose in practical application? Many people who have been in the construction industry for many years cannot explain it in detail.

What are the 6 types of structural steels?

Structural steel is a category of steel used for making construction materials in a variety of shapes and provides support to buildings of all kinds, that is made of a versatile type of carbon steel that’s available in a range of metal grades. They’re integral to weight distribution and ensure the integrity, safety, and durability of buildings, and the uses span everything from bridges to residential and commercial constructions, from parking garages to machine bases. Engineers have applied structural steel to millions of projects, creating massive skyscrapers and expansive bridges that have remained for hundreds of years.

Though structural steel shapes can be customized, there are actually six different types of structural steel: Angles, Beams, Bearing Piles, Channels, Hollow Structural Sections (HSS), and Plates.

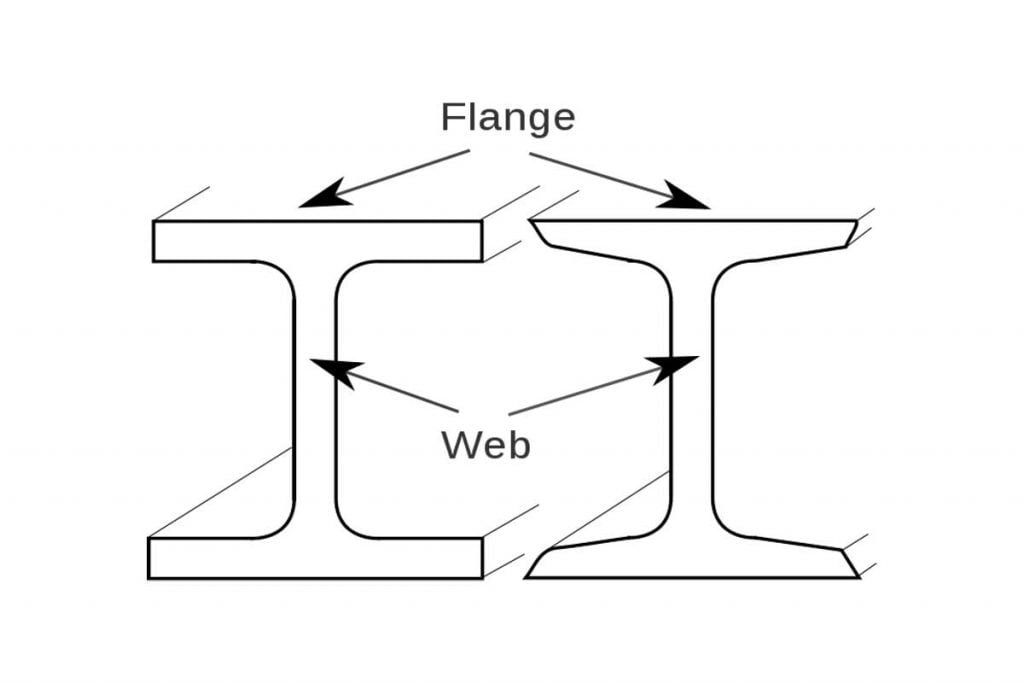

Common three most common types of structural steel members are H-beam (W-shape, wide flange), I-beam(S-shape), and the U-channel(C-shape).

structural beams

A beam is a structural element that supports a building or structure. It can be either primary support or secondary support and is generally used to bear a load from some other member, such as a foundation or the outer walls.

Beams are classified by their shapes (I-beams, H-beams, U-beams, box beams). The horizontal elements of the I and H beam are known as flanges, while the vertical element is called as the “web”. The web resists shear forces, and the flanges are designed to resist most of the bending moments that the beam experiences, which guarantees the integrity of a structure, adding stability and strength.

What is an I-beam?

I-beams are mainly divided into ordinary I-beams, light-duty I-beams, and wide-flange I-beams. According to the height ratio of the flange and web, it is divided into wide, medium, and narrow wide flange I-beams. The first two are produced in size 10-60, that is, the corresponding height is 10-60cm.

At the same height, lightweight I-beams have narrow flanges, and thin webs, and are lightweight. Wide flange I-beam, also known as H-beam, is characterized by two parallel legs and no slope on the inside of the legs. It belongs to economical section steel and is rolled on a four-high universal rolling mill, so it is also called a “universal I-beam”. Ordinary I-beam and light I-beam have formed national standards.

As the name suggests, I-beam is an “I”-shaped section of steel. The inner surface of the upper and lower flanges has an inclination, generally 1:6, which makes the flanges thin on the outside and thick on the inside. The cross-sectional properties of the main planes vary greatly, and it is difficult to exert the strength properties of steel in applications. Although thickened I-beams have also appeared in the I-beam market, the structure of I-beams has determined its torsional performance shortcomings.

What Are I-Beams Used For?

I-beams have a variety of important uses in the structural steel construction industry. They are often used as critical support trusses, or the main framework, in buildings. Steel I-beams ensure a structure’s integrity with relentless strength and support. The immense power of I beams reduces the need to include numerous support structures, saving time and money, as well as making the structure more stable. The versatility and dependability of I-beams make them a coveted resource to every builder.

5 tips to choose the right I-beam

- The builder chooses an I-beam with a web thickness that won’t fail, buckle, or ripple under tension.

- The flanges are chosen to prevent buckling locally, sideways, or torsionally.

- The builder will choose a thickness to minimize the deformation of the beam.

- A certain mass and stiffness are selected to prevent vibrations in the building.

- The strength of the I-beam’s cross-section should accommodate yield stress.

What is an H-beam?

H-beam is an economical section and high-efficiency profile with more optimized cross-sectional area distribution and a more reasonable strength-to-weight ratio. It is named because its cross-section is the same as the English letter “H”. Since all parts of the H-beam are arranged at right angles, the H-beam has the advantages of strong bending resistance, simple construction, cost-saving, and lightweight in all directions, and has been widely used.

H-beam has many differences compared with I-beam. The first is the flange, and the second is that the inner surface of the flange has no inclination, and the upper and lower surfaces are parallel. The cross-sectional properties of H-beams are significantly better than those of traditional I-beams, channel steels, and angle steels.

How are H beams made?

H beams are produced through a process called rolling. First, a beam blank (an unformed length of steel) is heated to make it malleable. The steel is then rolled using caliber rolls in order to form the beam into a rough H-shape. After the rolling is complete, the beam will undergo fine-tuning using a universal mill and an edging mill. Within the universal mill, there are more rollers called H-rolls and V-rolls (which stand for horizontal rolls and vertical rolls), which run along the top, bottom, and sides of the beam to shape it, while at the same time holding it in place. The H-shaped cross-section becomes fully formed when the material passes through the universal mill.

What Are H Beams Used For?

Wide flange beams (H beams) are structural support materials that are primarily used for building. Able to bear excessive amounts of pressure, they ensure structural integrity and stability.

The thickness of the H beam (wide flange beam) will determine the type of jobs it is best suited for. It is important to consider the force applied, the weight carried, and the tension and compression. Smaller sizes are normally used for jobs where the amount of pressure and weight will be minimal, while larger thicker sizes of steel wide flange beams are used to support structures that bear massive amounts of weight.

H-beam is 100 percent recyclable. This means it can be pulled from the ground and reused decades after use, making it one of the most environmentally friendly piling materials.

Which Is Stronger H Beam or I-Beam?

The cross-section of the H beam is stronger than the cross-section of the I beam, meaning it can bear a greater load. In comparison, the cross-section of an I beam can bear the direct load and tensile but cannot resist twisting because the cross-section is so narrow. This means that it can only bear force in one direction.

- H-beam: An H-beam has a thicker center web, which means it is often stronger.

- I-beam: An I-beam often has a thinner center web, which means it is often not able to take as much force as an h-beam.

Is the H beam same as the I Beam?

The difference between the H and I beams is the flange per band ratio. Compared to an I beam, the H beam consists of longer flanges and a thicker centre web. The flanges on an I beam are tapered. H-beam has wider flanges than I-beam, but I-beam has tapered edges. The width is the flange and the height is the web. The H beam tends to be heavier than the I beam, which is why some say it is better than the I beam, but this is subjective, as the H beam is generally heavier.

Top 17 differences between H-beam and I-beam

differences 1#: Shape

H beam resembles the shape of Capital H, while the I beam is the shape of a capital I.

differences 2#: Manufacturing

- I-beams are manufactured as a single piece throughout, while H-beam comprises three metal plates welded together.

- H-beams can be fabricated to any desired size, while the milling machine capacity limits the production of I-beams.

differences 3#: Weight

- H beams are heavier in weight as compared to I beam.

- H-beam: The H-beam is often a lot heavier than the I-beam, which means it can take more force.

- I-beam: With some buildings where weight and force on a wall may pose a structural issue, the I-beam may be better since it is often lighter.

differences 4#: Center Web

- H-beam: An H-beam has a thicker center web, which means it is often stronger.

- I-beam: An I-beam often has a thinner center web, which means it is often not able to take as much force as an h-beam.

- Web Thickness: H beam has a significantly thicker web as compared to the I beam.

differences 5#: Distance From Flange end To Web’s center

At first look, both H-section and I-section steel beams look similar, but there are some critical differences between these two steel beams that are essential to know.

In I-section, the distance from the flange end to the Web’s center is less, while in H-section, The distance from the flange end to the Web’s center is higher for the similar section of the I-beam.

differences 6#: Strength

- The h-section beam gives more strength per unit weight due to a more optimized cross-sectional area and an excellent strength-to-weight ratio.

- Generally, I-section beams are deeper than wide, making them exceptionally good at bearing load under local buckling. Furthermore, they are lighter in weight than H-section beams, so they will not take a significant load as H-beams.

differences 7#: Cross-section

- The I-section beam has a narrow cross-section suitable for bearing direct load and tensile stresses but is poor against twisting.

- In comparison, the H beam has a broader cross-section than the I beam, which can handle the direct load and tensile stresses and resist twisting.

differences 8#: Ease of Welding

- H-section beams are more accessible to weld due to their straight outer flanges than I-section beams.

- The h-section beam cross-section is more robust than the I-section beam cross-section; hence it can take a more significant load.

differences 9#: Moment of Inertia

- The Moment of Inertia for a beam determines its capacity to resist bending. The higher it will be, the less the beam will bend.

- H-section beams have wider flanges, high lateral stiffness, and greater moment of inertia than I-section beams, and they are more resistant to bending than I-beams.

differences 10#: Built-Up

- H-beam: An H-beam can possibly be built up which means it can be built up to any size or height.

- I-beam: An I-beam can only be built up as much as the manufacturer’s milling equipment allows.

differences 11#: Spans

- H-beam: H-beams can be used for spans up to 330 feet.

- I-beam: An I-beam may be used for spans of between 33 and 100 feet.

differences 12#: Flanges

- H-beam: H-beams have top and bottom flanges that stick out further from the web than the flanges on I-beams.

- I-beam: I-beams have top and bottom flanges, and they are shorter and not as wide as H-beams.

- H beam flanges have equal thickness and are parallel to each other, while I beam have tapered flanges with an inclination of 1: to 1:10 for better load-bearing capacity.

differences 13#: Rigidity

In general, H- Section beams are more rigid and can take a heavier load than I-section beams.

differences 14#: Number of Pieces

- The h-section beam resembles a single metal piece, but it has a bevel where three metal plates are welded together.

- Whereas an I-section beam is not produced by welding or riveting metal sheets together, it is only one section of metal entirely.

differences 15#: Economy

- An H-section beam is a more economical section with enhanced mechanical properties than an I-section beam.

- An I-section beam can be used for a span of up to 33 to 100 feet due to manufacturing limitations, while an H-section beam can be used for a span of up to 330 feet since it can be made in any size or height.

differences 16#: Mechanical difference

- Retaining wall H beams are more mechanically straightforward and are therefore quicker and cheaper to manufacture. H beams are easier to weld than I beams because the outer flanges are straight.

- The cross-section of the H beam is stronger than the cross-section of the I beam, meaning it can bear a greater load. In comparison, the cross-section of an I beam can bear the direct load and tensile but cannot resist twisting because the cross-section is so narrow. This means that it can only bear force in one direction.

- Retaining wall H beams are heavier than I beams, so they can bear a greater load

- The way that they are manufactured means that H beams can be produced up to 330 feet long, whereas I beams can only be produced up to 100 feet due to their complex shape and dimensions

differences 17#: Applications

At first, glance, retaining wall H beams seem like a better option, as they are cheaper and quicker to manufacture, and they generally have a greater load-bearing capacity. However, as with most choices in life, the ultimate decision depends on the situation.

Steel has been the material of choice in the construction industry for many years because it is strong, lightweight, and easily erected. It is also widely manufactured and durable. With a superior strength-to-weight ratio, retaining wall H beams are commonly used as supports for bridges, platforms, and mezzanines. They are also frequently used as support columns in residential building projects.

On the other hand, I beams have high tensile strength. This means they are excellent at bearing load under direct pressure. I beams are often used in the construction of steel-framed buildings and bridges.

H-section beams are ideal for mezzanines, bridges, platforms, and the construction of typical residential and commercial buildings. They are also used for the load-bearing column, trailer, and truck bed framing.

I-section beams are the adopted section for bridges, structural steel buildings, and the making of support frames and columns for elevators, hoists and lifts, trolley ways, trailers, and truck beds.

8 Criteria for H-Beam and I-Beam Design

The design of both I-beam and H-beam is governed by any of the following criteria:

- Deflection: Target criteria should be to minimize deformation

- Vibration: the stiffness and mass are should be decided based on Vibration tendency.

- Bending failure by yielding

- Bending failure by lateral torsional buckling

- Bending failure by local buckling

- Local yield due to high magnitude of concentrated loads.

- Shear failure

- Buckling or yielding of components

What are H-beam and I beam sizes H Beam Size And Weight Chart?

What do H beam sizes mean?

The designation of the H beam (wide flange beam) gives information about the width and weight per unit length. For example, W12 X 96 means 12 inches in depth and 96 pounds per foot weight per unit length.

Materials of wide flange beams are generally structural steels such as A36, A572, A588, and A992.

The designation of the H beam (wide flange beam) gives information about the width and weight per unit length. For example, W12 X 96 means 12 inches in depth and 96 pounds per foot weight per unit length. Depth values are generally approximate. For W12 x 96, the actual depth value is 12.71. Therefore the actual depth value is a dimension that must be checked while designing a structural steel system.

In regards to weight bearing capacity, individual piles can support as much as 1,000 tons. These piles are more efficient in dense soils that offer pile resistance at the tip for point-bearing capacity. When constructing a pile system on rock, steel H-piles are considered the best and most reliable option.

H Beam Size And Weight Chart

H beam size and weight chart: Wide Flange Series (HW)

| Grade | Size of the Section (in mm) | Cross- Sectional Area | Weight | Member Designation | ||||

| H | B | t1 | t2 | r | cm2 | kg/m | ||

| 100 X 100 | 100 | 100 | 6 | 8 | 10 | 21.9 | 17.19 | 100x100x6x8 |

| 125 X 125 | 125 | 125 | 6.5 | 9 | 10 | 30.31 | 23.79 | 125x125x6.5×9 |

| 150 X 150 | 150 | 150 | 7 | 10 | 13 | 40.55 | 31.83 | 150x150x7x10 |

| 175 X 175 | 175 | 175 | 7.5 | 11 | 13 | 51.43 | 40.37 | 175x175x7.5×11 |

| 200 X 200 | 200 | 200 | 8 | 12 | 16 | 64.28 | 50.46 | 200x200x8x12 |

| 200 | 204 | 12 | 12 | 16 | 72.28 | 56.74 | 200x204x12x12 | |

| 250 X 250 | 250 | 250 | 9 | 14 | 16 | 92.18 | 72.36 | 250x250x9x14 |

| 250 | 255 | 14 | 14 | 16 | 104.68 | 82.17 | 250x255x14x14 |

H beam size and weight chart: Medium Flange Series (HM)

| Grade | Size of the Section (in mm) | Cross- Sectional Area | Weight | Member Designation | ||||

| 150 X 100 | 148 | 100 | 6 | 9 | 13 | 27.25 | 21.39 | 148x100x6x9 |

| 200 X 150 | 194 | 150 | 6 | 9 | 16 | 39.76 | 31.21 | 194x150x6x9 |

| 250 X 175 | 244 | 175 | 7 | 11 | 16 | 56.24 | 44.15 | 244x175x7x11 |

| 300 X 200 | 294 | 200 | 8 | 12 | 20 | 73.03 | 57.33 | 294x200x8x12 |

H beam size and weight chart: Narrow Flange Series (HN)

| Grade | Size of the Section (in mm) | Cross- Sectional Area | Weight | Member Designation | ||||

| 175 X 90 | 175 | 90 | 5 | 8 | 10 | 23.21 | 18.22 | 175x90x5x8 |

| 200 X 100 | 198 | 99 | 4.5 | 7 | 13 | 23.59 | 18.52 | 198x99x4.5×7 |

| 200 X 100 | 200 | 100 | 5.5 | 8 | 13 | 27.57 | 21.64 | 200x100x5.5×8 |

| 250 X 125 | 248 | 124 | 5 | 8 | 13 | 32.89 | 25.82 | 248x124x5x8 |

| 250 X 125 | 250 | 125 | 6 | 9 | 13 | 37.87 | 29.73 | 250x125x6x9 |

I Beam Size And Weight Chart

I-beam size chart for some common structural sections are provided below:

| Designation | Depth – H – (mm) | Width – B – (mm) | Web Thickness – d – (mm) | Cross Sectional Area (cm2) | Weight (kg/m) | |

| UB 127 x 76 x 13 | 127 | 76 | 4 | 16.5 | 13 | |

| UB 152 x 89 x 16 | 152.4 | 88.7 | 4.5 | 20.3 | 16 | |

| UB 178 x 102 x 19 | 177.8 | 101.2 | 4.8 | 24.3 | 19 | |

| UB 203 x 102 x 23 | 203.2 | 101.8 | 5.4 | 29.4 | 23.1 | |

| UB 203 x 133 x 25 | 203.2 | 133.2 | 5.7 | 32 | 25.1 | |

| UB 203 x 133 x 30 | 206.8 | 133.9 | 6.4 | 38.2 | 30 | |

| UB 254 x 102 x 22 | 254 | 101.6 | 5.7 | 28 | 22 | |

| UB 254 x 102 x 25 | 257.2 | 101.9 | 6 | 32 | 25.2 | |

| UB 254 x 102 x 28 | 260.4 | 102.2 | 6.3 | 36.1 | 28.3 | |

| UB 254 x 146 x 31 | 251.4 | 146.1 | 6 | 39.7 | 31.1 | |

| UB 254 x 146 x 37 | 256 | 146.4 | 6.3 | 47.2 | 37 | |

| UB 254 x 146 x 43 | 259.6 | 147.3 | 7.2 | 54.8 | 43 | |

| UB 305 x 102 x 25 | 305.1 | 101.6 | 5.8 | 31.6 | 24.8 | |

| UB 305 x 102 x 28 | 308.7 | 101.8 | 6 | 35.9 | 28.2 | |

| UB 305 x 102 x 33 | 312.7 | 102.4 | 6.6 | 41.8 | 32.8 | |

| UB 305 x 127 x 37 | 304.4 | 123.4 | 7.1 | 47.2 | 37 | |

| UB 305 x 127 x 42 | 307.2 | 124.3 | 8 | 53.4 | 41.9 | |

| UB 305 x 127 x 48 | 311 | 125.3 | 9 | 61.2 | 48.1 | |

| UB 305 x 165 x 40 | 303.4 | 165 | 6 | 51.3 | 40.3 | |

| UB 305 x 165 x 46 | 306.6 | 165.7 | 6.7 | 58.8 | 46.1 | |

| UB 305 x 165 x 54 | 310.4 | 166.9 | 7.9 | 68.8 | 54 | |

| UB 356 x 127 x 33 | 349 | 125.4 | 6 | 42.1 | 33.1 | |

| UB 356 x 127 x 39 | 353.4 | 126 | 6.6 | 49.8 | 39.1 | |

| UB 356 x 171 x 45 | 351.4 | 171.1 | 7 | 57.3 | 45 | |

| UB 356 x 171 x 51 | 355 | 171.5 | 7.4 | 64.9 | 51 | |

| UB 356 x 171 x 57 | 358 | 172.2 | 8.1 | 72.6 | 57 | |

| UB 356 x 171 x 67 | 363.4 | 173.2 | 9.1 | 85.5 | 67.1 | |

| UB 406 x 140 x 39 | 398 | 141.8 | 6.4 | 49.7 | 39 | |

| UB 406 x 140 x 46 | 403.2 | 142.2 | 6.8 | 58.6 | 46 | |

| UB 406 x 178 x 54 | 402.6 | 177.7 | 7.7 | 69 | 54.1 | |

| UB 406 x 178 x 60 | 406.4 | 177.9 | 7.9 | 76.5 | 60.1 | |

| UB 406 x 178 x 67 | 409.4 | 178.8 | 8.8 | 85.5 | 67.1 | |

| UB 406 x 178 x 74 | 412.8 | 179.5 | 9.5 | 94.5 | 74.2 | |

| UB 457 x 152 x 52 | 449.8 | 152.4 | 7.6 | 66.6 | 52.3 | |

| UB 457 x 152 x 60 | 454.6 | 152.9 | 8.1 | 76.2 | 59.8 | |

| UB 457 x 152 x 67 | 458 | 153.8 | 9 | 85.6 | 67.2 | |

| UB 457 x 152 x 74 | 462 | 154.4 | 9.6 | 94.5 | 74.2 | |

| UB 457 x 152 x 82 | 465.8 | 155.3 | 10.5 | 104.5 | 82.1 | |

| UB 457 x 191 x 67 | 453.4 | 189.9 | 8.5 | 85.5 | 67.1 | |

| UB 457 x 191 x 74 | 457 | 190.4 | 9 | 94.6 | 74.3 | |

| UB 457 x 191 x 82 | 460 | 191.3 | 9.9 | 104.5 | 82 | |

| UB 457 x 191 x 89 | 463.4 | 191.9 | 10.5 | 113.8 | 89.3 | |

| UB 457 x 191 x 98 | 467.2 | 192.8 | 11.4 | 125.3 | 98.3 |