Two Rules for Bend Radius in Pipe or Tubing Bending

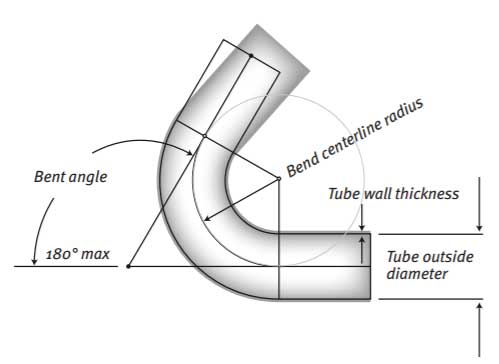

When we talk about bend radius it refers to the radius measured to the center line of the tube. Every CNC pipe/tubing bending machine will have a different set of draw bend radius tooling based on previous jobs that they… Read More »Two Rules for Bend Radius in Pipe or Tubing Bending