Precision Stretch Forming of Titanium and Aluminum Alloy Profile Components

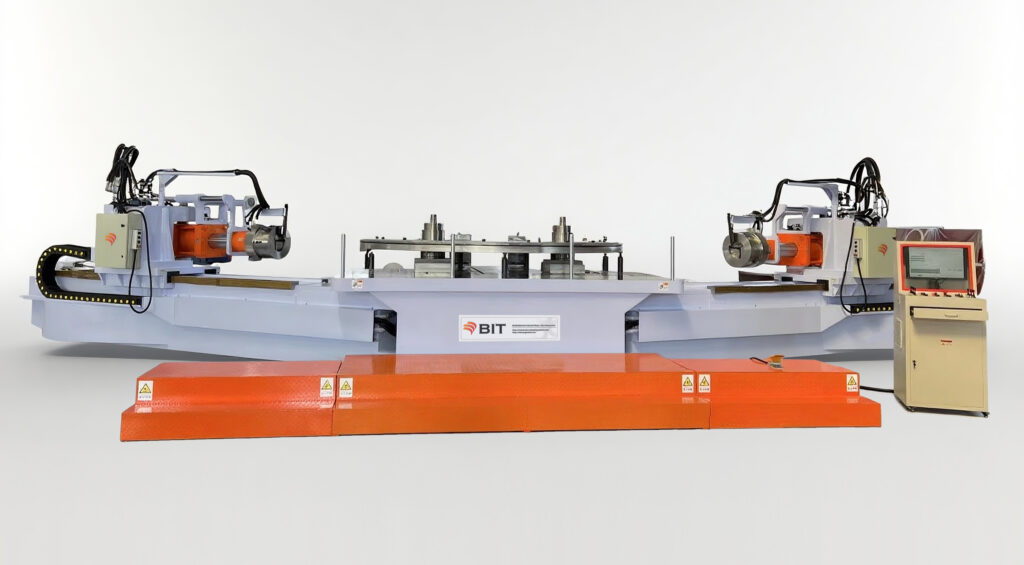

PBF-AS CNC 2D/3D Stretch Forming Machine

So Far, China’s Aerospace Industry Has Only Used PBF-AS Servo CNC Stretch Forming Equipment.

PBF-AS CNC Stretch Forming Machine

PBF-AS CNC Stretch Forming Machines are engineered for high precision and durability, designed to meet the rigorous forming requirements of the aerospace, transportation, and new energy industries.

With advanced PC-based CNC control, intelligent force-position coordination, and self-learning forming programs, the PBF-AS Stretch Forming Machine delivers consistent forming results, minimizes rebound variation, and allows smooth production of multi-radius, high-precision aerospace structural parts.

Built on dual-arm servo-hydraulic architecture, the PBF-AS series ensures stable torque, exceptional accuracy, and superior repeatability for both aluminum and titanium alloy components. Each machine is produced and tested in full compliance with international ISO and IEC standards, guaranteeing excellent structural rigidity, thermal stability, and long-term reliability.

Advanced Servo-Hydraulic Control System

PBF-AS stretch forming machines are equipped with a state-of-the-art servo-hydraulic system that delivers smooth, precise, and stable motion control throughout the forming process. Each hydraulic cylinder is independently managed by CNC, ensuring synchronized multi-axis operation and accurate force distribution.

The closed-loop servo control maintains precise pressure and displacement, providing consistent forming results even under complex load conditions. Both force and position control modes are available, minimizing springback and guaranteeing repeatable accuracy across different materials and shapes.

High-efficiency hydraulic components and intelligent temperature control ensure reliable 24-hour operation with low noise, minimal heat buildup, and reduced energy consumption — achieving long-term stability and superior performance.

High-Precision CNC Stretch Forming Control

The high-precision stretch forming control system of PBF-AS stretch forming machines ensures exceptional accuracy and repeatability during forming. Each axis is independently controlled by CNC for precise synchronization between stretching and bending movements.

The stretch forming control system supports both force and position control modes, allowing smooth transitions and minimal material springback. Real-time feedback ensures consistent forming pressure, superior surface finish, and dimensional accuracy.

With an intuitive PC-based interface and intelligent self-learning software, PBF-AS machines enable easy operation, automatic parameter generation, and high productivity — ideal for aerospace, rail, and automotive aluminum profile forming.

Robust Structural Design and Mechanical Reliability

Engineered with a dual-arm welded steel frame, the PBF-AS CNC Stretch Forming Machine delivers outstanding rigidity, vibration resistance, and long-term mechanical stability. All critical assemblies are stress-relieved and precision-machined to ensure geometric accuracy throughout years of continuous operation.

Each stretch forming arm operates via an independent servo-hydraulic actuator, providing synchronized or individual motion control to handle asymmetric profiles and complex geometries. The precision-ground mold table and reinforced frame offer reliable support for heavy tooling and large aluminum extrusions, maintaining smooth motion and minimal deformation even under full-load forming conditions.

This robust structural configuration guarantees high repeatability, excellent stability, and extended service life — ensuring consistent performance in demanding, 24-hour production environments.

Energy Efficiency and Sustainable Performance

The PBF-AS CNC Stretch Forming Machine integrates an energy-saving servo-hydraulic drive system that automatically adjusts output according to real-time forming load. This intelligent power management reduces idle energy loss, minimizes oil temperature rise, and significantly lowers overall operating costs.

High-efficiency pumps, low-friction hydraulic circuits, and advanced temperature regulation allow stable 24-hour operation with minimal heat buildup and noise. The closed hydraulic system minimizes leakage and contamination, extending the service life of key components while maintaining consistent forming performance.

Customization and Application Versatility

Designed for flexibility, the PBF-AS CNC Stretch Forming Machine can be configured for various profile types and materials — including aluminum, titanium, and high-strength alloys. The modular clamping system and customizable tooling interface enable rapid changeovers between different part geometries, reducing downtime and improving throughput.

Its intelligent control software supports multi-radius, variable cross-section, and compound curvature forming, making it ideal for complex aerospace panels, rail components, and automotive structures. With integrated data storage and remote diagnostic functions, PBF-AS machines offer easy process traceability and seamless integration into smart factory environments.