Sheet Metal and Aluminum Extrusions Stretch Bending

Extrusion and Sheet Stretch Forming

Stretch forming/bending can be used to create various shapes, including gentle curves, compound curves, and even sharp angles. It makes it ideal for creating structural components with precise dimensions and contours that can be used with a variety of metals, including aluminum, steel, and titanium.

During stretching, it is crucial to control the stretch force to prevent material breakage; simultaneously, surface wrinkling, cross-sectional distortion, and longitudinal twisting must be avoided.

The Stretch Forming Process follows a precise, step-by-step workflow to ensure accuracy, consistency, and high-quality results. The full process is shown below:

Stretch Forming Process Review → Final Stretch Bending Drawing → Stretch Forming → Dimensional & Curvature Inspection → Aging Treatment → Surface Pre-Treatment → Coating → Packaging & Storage

Stretch Forming Process Review

Due to the diverse requirements of aluminum profile applications, most aluminum extrusions have different structures, a wide variety of types, varying cross-section sizes, and complex designs, resulting in varying processing difficulty. Therefore, for each project, before opening the aluminum extrusion die after completing the stretch bending profile design drawings, it is recommended to conduct a preliminary feasibility review of the stretch forming process drawings. Key evaluation points include: profile wall thickness and cross-section, the degree of deformation after bending, material dimensions for each model and curvature, and whether the final product can be assembled, with feedback provided accordingly.

Final Stretch Forming Drawing Preparation and Evaluation

Before production or tooling begins, a feasibility review helps identify forming limits, material concerns, and equipment needs. The guidelines below summarize the key factors to evaluate stretch forming and stretch bending performance across architectural, automotive, and aerospace applications.

- General Principles The more radii involved, the smaller the radii, and the longer the material length, the higher the difficulty of the stretch forming process and the lower the processing efficiency. It is recommended to minimize the variety of radii and consolidate length specifications whenever possible.

- First Article Verification If the stretch forming results cannot be fully assured, it is advisable to produce an assembly first article. Only after the first article is reviewed and approved should mass production begin; otherwise, large-volume material scrap may occur. All first-article requirements should be provided at once, as repeated adjustments significantly increase the difficulty of coordination with the manufacturer.

- Arc Length Limitation The effective arc length of the stretch-formed aluminum profile must not exceed a half circle (180°).

- Wall Thickness Requirements Aluminum extrusions with excessively thin walls are not suitable for stretch forming. Thin-wall sections experience a large amount of elongation and are prone to cracking, especially when the bending radius is small. Smaller radii generate greater elongation and impose stricter wall-thickness requirements.

- Large Hollow Cavity Considerations Extrusions with large cavities (e.g., 100 × 50 mm and above) tend to experience outer-arc concavity after stretch forming. The smaller the radius, the more pronounced the concavity, commonly seen in beams, mullions, rectangular tubes, and decorative aluminum profiles.

- Inclined-Angle Profiles Profiles with inclined angles exhibit larger dimensional deviations after stretch forming. The angle must be at least 5°; smaller angles cannot be processed reliably.

- Large Cross-Section Limitations For aluminum profiles with a long side exceeding 200 mm, the bending radius must not be less than 2 meters. In general, large cross-section extrusions cannot be formed to small radii.

- Equipment Requirements Large cross-section aluminum extrusions must be processed on large-tonnage stretch forming machines. The minimum material length must exceed 3 meters; shorter pieces cannot be stretch-formed effectively.

- Common Stretch Forming Applications In the architectural industry, stretch forming is widely applied to curtain wall aluminum profiles, window frames, and other façade components. In the automotive sector, stretch bending is used for aluminum extrusions such as bumper beams, guide rails, and roof-rack components. In aerospace applications, stretch forming is crucial for high-performance parts including fuselage skins, wing beams, and door-frame extrusions.

Preparation of Auxiliary Materials

Custom Filling Materials: Some open-section and closed-section aluminum extrusions have complex structures. To prevent deformation during stretch forming, custom filling materials must be prepared in advance. For open-section profiles, the post-stretching deformation must not exceed ±1 mm. Special unit profiles that will be assembled later must fit precisely. For closed-section profiles, the filling should ensure that the cross-sectional deformation tolerance after stretch forming remains within +1.5 mm.

Custom Clamps: During stretch forming, the hydraulic stretch forming machine requires its two clamps to securely hold both ends of the profile. Therefore, custom clamps must be designed according to the cavity structure of the profile prior to forming.

Custom Dies: Each stretch-formed aluminum extrusion requires a custom steel die based on the profile’s cross-sectional dimensions, material, bend radius, and effective arc length. The steel die is installed on the hydraulic stretch forming machine’s working table before the profile is formed.

Aluminum Extrusions Stretch Forming Material Preparation

Successful stretch forming of aluminum extrusions begins with proper material preparation. Before production, profiles must meet the correct alloy condition, length specifications, and supply requirements to ensure stable deformation and consistent forming quality. The following guidelines summarize the key material and batching standards essential for achieving reliable stretch forming results.

Proper material preparation is essential for ensuring stability and consistency during the stretch forming of aluminum extrusions. Before production begins, all profiles must meet specific technical requirements. Aluminum extrusions used for stretch forming should be supplied in the 6063-T4 (non-aged) condition to provide sufficient ductility, allowing the material to deform uniformly under tension without cracking. For profiles with a bending radius of less than 1500 mm, the total material length must include the effective arc length plus a 600 mm allowance for the clamping jaws. For radii between 1500 mm and 3000 mm, the same calculation applies, but the cutting lengths should be standardized to 3500, 4000, 4500, or 5000 mm to improve processing efficiency and simplify stock control. When the radius exceeds 3000 mm, the required lengths should fall between 4000 and 6500 mm to ensure stable gripping and prevent forming deviations.

Each stretch forming batch must also include two additional spare pieces for every processing code, allowing for machine setup, testing, and unexpected material loss. For material procurement planning, projects requiring less than 10 tons should complete all material preparation in a single batch, while those exceeding 10 tons may be divided into no more than two batches. These standardized preparation requirements help improve stretch forming quality, reduce material waste, and ensure a more efficient and reliable production workflow for aluminum extrusions stretch forming.

Stretch Forming Process of Aluminum Extrusions

Stretch Forming Process

Stretch forming of aluminum extrusions ensures precise shaping with minimal springback. By pre-stretching and bending over a die, the process achieves uniform stress distribution, high accuracy, and reliable final profiles for architectural, automotive, and aerospace applications.

The stretch forming process for aluminum extrusions typically involves three main steps. Step 1: the profile undergoes pre-stretching to eliminate elastic deformation and bring the material into the plastic deformation range. Step 2: the profile is bent over a forming die to achieve the desired shape. Step 3: a secondary stretch may be applied, depending on the production requirements.

In practice, the secondary stretching step is optional. The standard operation is as follows: the ends of the aluminum extrusion are clamped securely, and a significant pre-stretching force is applied, slightly above the material’s yield strength, typically around 1.1 times the yield value. The clamping devices then move, and as the extrusion contacts the forming die, a forming moment develops at the midsection of the arc, dividing the extrusion into two forming zones. As the clamps continue to move, the forming moment and the degree of deformation increase. When the desired shape is achieved, the movement stops. After forming, the extrusion is not immediately removed; the stretching force is increased for a second pass to finalize the shape.

Characteristics

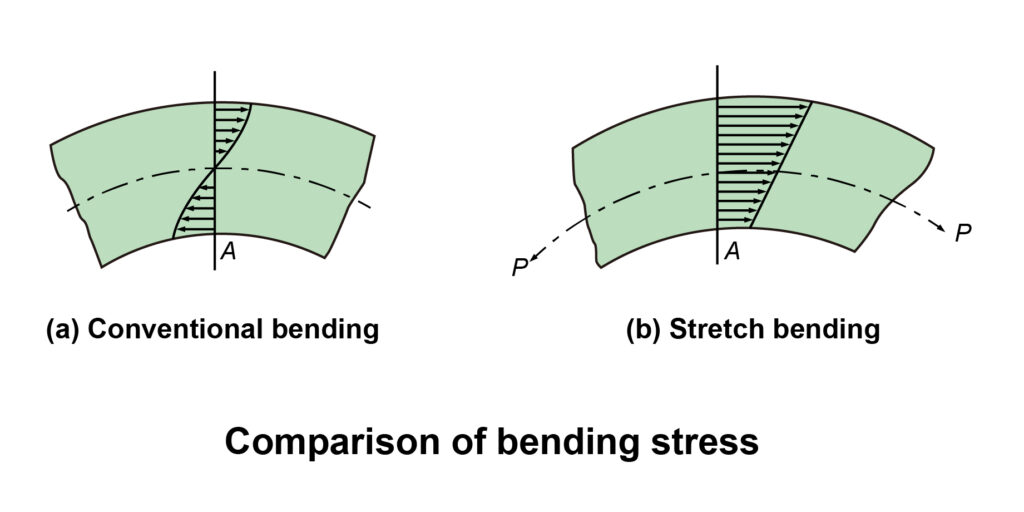

Compared to other bending methods, the distribution of tangential stress within a workpiece during stretch forming is significantly different. Conventional bending techniques, such as press bending or roll bending, are single-axis processes in which the inner layer of the profile is in compression, the outer layer is in tension, and the neutral axis remains unchanged. As illustrated in Figure A, during stretch forming, an additional tensile force P is applied along the bending direction. This increases the tensile stress on the outer layer, while the inner layer initially experiences compressive stress, which quickly decreases and eventually transitions to tension. When the tensile stress at the innermost point A exceeds the material’s yield stress (σₛ), removing the force P allows the aluminum extrusion to largely retain the stretch-formed shape, resulting in minimal springback.

Filling Methods by Bend Radius

The main filling methods of stretch forming techniques are classified according to the bend radius:

1. Bend radius greater than 15,000 mm: In most cases, no internal filling is required, and the profile can be bent directly.

2. Bend radius between 1,500 mm and 15,000 mm: The filling method depends on the profile type. Open-section profiles are filled with custom PVC boards, while hollow-section profiles are filled with sand.

3. Bend radius less than 1,500 mm: For open-section profiles, PVC boards are still used for filling. Hollow-section profiles require a chemical filler to minimize deformation during the bending process.

Inspection and Quality Control After Stretch Forming

- Profile Inspection After stretch forming, the profile is placed on a standard inspection platform to check for visual deformation, flatness, and torsion within acceptable ranges. The profile radius is then verified using a calibrated radius gauge (effective arc length 1000 mm ±1 mm). If all criteria are met, the workpiece is considered a qualified stretch-formed part.

- Trial Assembly for Coordinated Profiles For profiles that need to be assembled later, trial fitting is conducted after stretch forming to ensure that customers can process and assemble the components smoothly.

Notes: The banner image at the top shows the entire stretch forming process of a automaker’s roof rails. Here is its video URL: https://youtu.be/0-RXNcyA62Y?si=Bpx4nzfWT0Nd3M_i